Ralph Lauren’s Olympic uniforms were made in China with a promise next time they will be made in America. My question is where in America? We pushed this industry away from our skilled hands into the hands of those living in other countries. Shuttered sewing factories can be found all over the nation, including San Antonio where my family had a contract sewing factory in the 1990s. (Just a reminder I married into the Jucker family, and I come from San Antonio.)

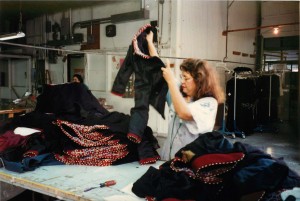

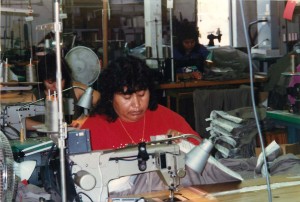

This post is about one of my “previous lives,” and as you read this post take a good look at the faces of those who sewed in America. Look in to their souls. These are our next door neighbors, and they were my colleagues and work family before moving to Houston.

San Antonio, Texas, was a hub of sewing in the USA for over a century. So many talented seamstresses and tailors lived and worked in SA making garments for the military, Levis, band and school uniforms, children’s clothing, men’s shirts, Fiesta gowns and more. Support businesses existed such as commercial launderers, patternmakers, cutters, stone washers, sewing machine repair and parts shops and again more. The loud hum of the sewing machine could be heard throughout the city.

Our family’s factory, Monarch Apparel, existed only from 1992-1996 (it may have begun in 1993 – I can’t remember). We employed at one time over 80 talented, skilled people. It began when a manufacturer leasing the building owned by my parents did not pay their tax bill. The employees of the factory went to my father and asked him to buy it from the IRS and keep it open, so they could work. My father took the landlord’s lien, no one bid on it, and bought the assets for a small sum. The IRS was betting on our family to keep the factory running and bringing in more tax dollars by keeping people employed. A good bet on the part of the IRS.

We sewed for Double D Ranch, Westmoor Manufacturing (remember those Brooks and Dunne flame shirts and Mo Betta shirts made famous by Garth Brooks), Sunny South, Liza Lynn, David James, CI Castro and many others.

We lasted four years and lost a good deal of money. With the rise of NAFTA and other off shore competition and increased competition from the home sewing trade (which at the time was illegal), we simply could not make a living sewing in the United States. The government had allowed this industry to leave our nation.

In 1996, we finally shut down (New York Times, January 15, 1996, In Small-Town Texas, the Sewing Stops talks of the demise of the industry in Texas). I remember the day I told our employees we were closing. I had arranged for jobs for those last team members at CI Castro, a children’s clothing manufacturer. The next week would be the last week they would receive checks, and I asked them to come for them that next Wednesday. Two hours before they were to receive their final checks, Mr. Castro called me to tell me no one had come to his factory to apply for a job. I could not understand it.

When they came for their checks I said Mr. Castro was waiting for them and asked why they had not gone to him. Their response was they were waiting for us to simply change our name and reopen. That is what always happened. I explained – not this time. We were paying our bills and closing our doors and to go to Mr. Castro while he still had openings.

Approximately 20 of Monarch Apparel’s sewers went to him, and when he finally had to move his production off shore to compete, he kept a small sample and quality team – most of which came from our factory. Left behind in America were some of the last skilled in the fine art of sewing.

They could sew anything, double needle stitching, piping, beading and could even sew a zipper into a garment. Zippers of yesterday – not what we see today where the metal of the zipper is exposed, but a hidden zipper. Exposed zippers are supposedly fashionable, but I believe it is simply economics – they are less expensive and require less skill, so the sewer can be paid less. Every time I see an exposed zipper I want to cringe. It is simply a reminder of a lost industry – a lost art.

Our government laments over the Olympic garments being made in China, but our government needs to take responsibility for sending the industry away and create incentives to bring the industry back. Train the next generation while there are still some around who know and remember the industry and the skills. Bring these manufacturing jobs back while there are still factory supervisors alive and living in the United States. From first hand experience I will tell you it is a hard job. I learned the basics of sewing factory supervision, but I could never master it.

We had a sewing floor supervisor Josie De Los Santos, of blessed memory, who began sewing in her teens and was a part of a sewing factory almost until she died in her 70s. She was an amazing woman. She lived and breathed sewing and brought her enthusiasm to all around her, along with her desire to produce quality products.

I hope by the time of the next Olympics some new contract sewing factories return to America. The uniforms are a small production run of various sizes. Basically a production nightmare, so no large factory would want to make this type of order. Only a contract sewer would be appropriate.

I also hope the next Josie De Los Santos is reading this article and can be a part of the next great wave of sewing in the USA. Writing my thoughts with Josey in mind, I encourage you to talk with your Congressional Representatives and Senators to bring back this industry to our great country while there are still those who can train them.

And let us all wear proudly once again MADE IN THE USA.